SEWAGE TREATMENT PLANT

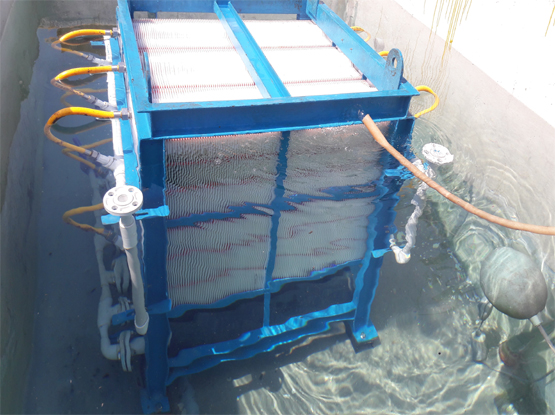

MBR (Membrane Bioreactor)

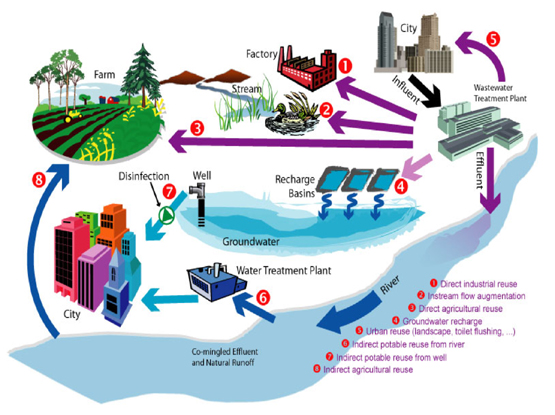

The Membrane Bioreactor (MBR) process is based on a treatment scheme wherein suspended growth activated sludge process micro-porous membranes for solid/liquid separation are applied instead of secondary clarifiers. It also creates a barrier for some pathogens which normally remain untreated by chlorine dosing. Thus making the whole treatment arrangement really compact producing quality effluent idle for various reuse applications.

MBBR (Moving Bed Bioreactor)

The MBBR systems are based on the principal of increasing the surface area for enhanced biological treatment without increasing the plant footprint. The treatment reactors are filled with specially engineered media carriers to provide a larger surface area for development of bacterial biofilm.

FABR (Fluidized Aerobic Bed Reactor)

FBR is a substitute of conventional treatment processes answering to its inadequacy like large plant footprint and high power consumption. FBR offers an effective alternate to the conventional systems made unviable due to scarcity of open space, geographical network of piping, high power and land cost.

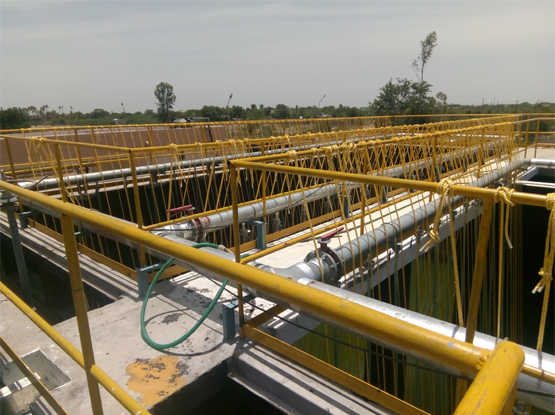

SAFF (Submerged Aerobic Fixed Film)

This treatment scheme is based on fixed film technology amalgamated along with various aeration systems, making it a highly efficient biological treatment process.. With the higher area surface higher organic loading rates are enabled, thus reducing the overall size required of the aeration tank. This leads to a considerable reduction in civil costs. SAFF sustains excellent microbial growth in tough conditions and also capable of handling fluctuating shock loads.

SBR (Sequencing Batch Reactor)

SBR process is based upon an idea that sewage is generated in batches corresponding with time. The treatment consists of phases fill, react, settle, and release. In the system the reaction tank is filled with raw wastewater.